Fitting Spur Gear

ASG, Fitting Spur Gear

Valve spur gears are primarily used to operate shut-off units such as sliders and valves. In order to move a valve or a slider out of the idle state in particular, increased torque is required. These gearboxes have a predetermined ratio of one-stage between 1:2.0 to 1:4.5 and two-stage between 1:2.75 to 1:12.0. This ratio increases the opening or closing force so that the gearbox can be operated using a handwheel or a flange rotary drive.

The installation position of the spur gear can be freely selected. However, the preferred installation position is with the drive shaft pointing downwards.

Spur gears ASG, structural design

Alternatively, the gearbox housing can be made of gray cast iron (quality EN-GJL-250) or nodular cast iron. The degree of protection of the gearbox is standard IP 65 according to EN 60 526. Due to the diverse use of the gearboxes in pipeline construction for supply lines, but also for shutting off lines in the chemical and petrochemical industries, there are a large number of connection flanges that are prescribed in the respective specialist area. Flanges according to DIN 3210 in sizes G1 to G7 are also available on the inlet side.

The application torques for the respective size are compiled as follows:

| Fitting Spur Gear | Torque | Gear Input | Gear Output |

| Type | [Nm] | DIN 3210 | DIN 3210 |

| ASG 30 | 300 | G0 ; G1/2 | G1 |

| ASG 60 | 600 | G0 ; G1/2 | G2 |

| ASG 125 | 1250 | G0 ; G1/2; G3 | G3 |

| ASG 250 | 2500 | G1/2; G3; G4 | G4 |

| ASG 500 | 5000 | G1/2; G3; G4 | G5 |

| ASG 1000 | 10000 | G1/2; G3; G4 | G6 |

| ASG 2000 | 16000 | G3; G4; G5 | G7 |

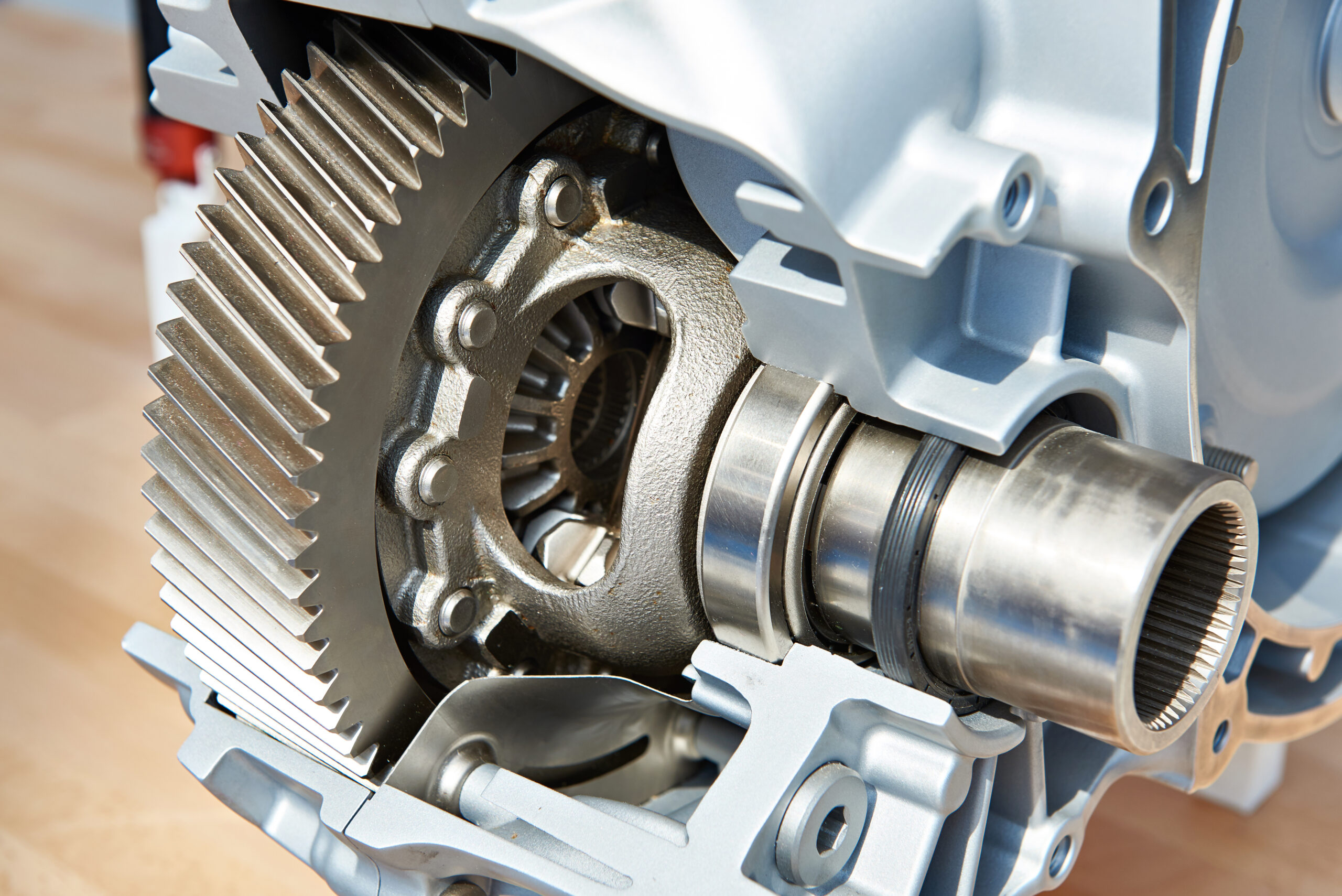

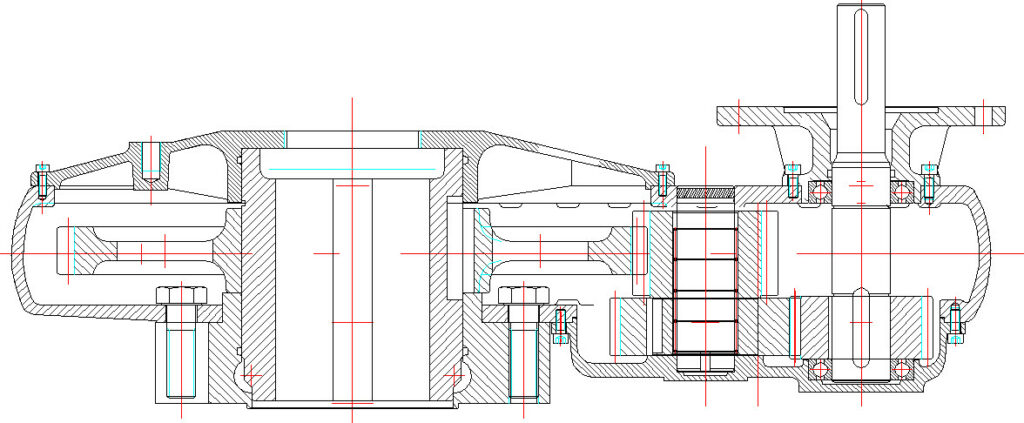

Depending on the type and size of the gear ratio, the spur gear is designed in one or two stages. Standard gear ratios for all gearboxes are 2:1 / 3:1 / 4:1 / 6:1 / 8:1 / 12:1. The intermediate shaft that is always present means that the direction of rotation of the input shaft and output shaft is the same. The drive pinion and the idler wheels are made of wear-resistant tempered steel according to DIN 17200. These parts are stored using roller bearings. The drive wheel made of nodular cast iron (up to quality EN-GJS-600) according to DIN 1693 has plain bearings.

In a design of the spur gear with connection form “A” at the gear outlet, as shown in the picture above, the threaded bushing is made of high-quality special bronze. The axial forces that occur are absorbed by roller bearings. Spindle protection tubes of the required length can be installed to protect the through-feed spindles.

In order to enable the largest possible spindle for adjusting the actuator, the threaded bushing is also designed to be as large as possible to ensure sufficient passage. The (ASG) fittings spur gears are designed for short-term operation (not regular operation with constant operation) and are supplied ready for operation with adhesive grease.